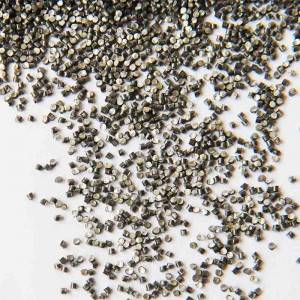

Bee Waya Shot/Ọhụrụ Waya

Ụdị/ nha:Φ0.2mm-2.8mm

Nkọwa ngwaahịa:

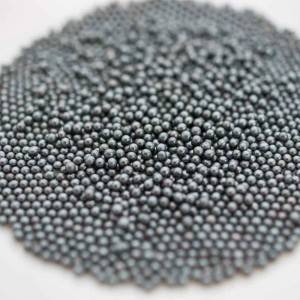

A na-arụpụta Cut Waya Shot site na waya dị elu nke a na-egbutu n'ogologo ihe dịka dayameta ya.Enwere ike iji eriri Carbon Steel, igwe anaghị agba nchara, Aluminom, Zinc, Nickel Alloy, Copper ma ọ bụ ọla kọpa ndị ọzọ.Ọ ka nwere akụkụ dị nkọ site na ọrụ ịkpụ.Dị ka-ebipụ waya ogbugba bụ irè ihicha abrasive ma ọ bụ adabara ogbugba peening ngwa ebe nkọ n'ọnụ nwere ike imebi ndụ ike ọgwụgwụ.

The hardness nke ọhụrụ waya nwere ike iru 50-60HRC, ọbụna karịa 60HRC, na ndụ dị ogologo karịa ochie wire.And agba nke ọhụrụ ịcha waya ogbugba bụ ihe na-egbuke egbuke, adabara nnukwu workpiece nke nwere chọrọ n'elu nkedo. .

Nkọwapụta igodo:

| Atumatu | Nkọwapụta | UZỌ anwale | |||

| NKWUKWU kemikal |

| 0.45-0.75% | P | ≤0.04% | ISO 9556:1989 ISO 439:1982 ISO 629:1982 ISO 10714:1992 |

| Si | 0.10-0.30% | Cr | / | ||

| Mn | 0.40-1.5% | Mo | / | ||

| S | ≤0.04% | Ni | / | ||

| MICROTRUCTURE | Pearlite mebiri emebi, netwọk carbide≤klas 3 | GB/T 19816.5-2005 | |||

| Njupụta | 7.8g/cm³ | GB/T 19816.4-2005 | |||

| Mpụga | Cylindrical udi, flat udi≤10%, trimming na burrs ≤18% | Anya | |||

| Ike | HRC40-60 | GB/T 19816.3-2005 | |||

Uru nke Steel Cut Waya Shot

Ogologo Ogologo kacha elu

N'ihi nhazi ime ya arụpụtara nke na-enweghị ntụpọ dị n'ime ya (mgbawa, porosity na shrinkage), ịdịte aka nke Cut Waya Shot dị ukwuu karịa mgbasa ozi ọla ndị ọzọ a na-ejikarị.

Nkwekọrịta kachasị

Cut Waya Shot Media nwere nkwekọ kachasị elu site na urughuru gaa na nha, ọdịdị, ike siri ike na njupụta.

Nguzogide kacha elu maka mgbaji

Cut Waya Shot Media na-achọ ịka nká wee na-adị ntakịrị karịa ka ọ na-agbaji n'ime akụkụ ahụ gbajiri ihu dị nkọ, nke nwere ike imebi akụkụ ahụ.

Ọgbọ Uzu Ala ala

Cut Wire Shot na-adịte aka karịa ma na-eguzogide mgbaji, na-ebute ọnụ ọgụgụ ọgbọ uzuzu dị ala.

Mmetọ elu ala

Cut Waya Shot enweghị mkpuchi Iron Oxide ma ọ bụ hapụ Iron Oxide residue—akụkụ dị ọcha ma na-enwu gbaa.