-

Na-ebu Angular Steel Grit

Bearing Angular Steel Grit bụ nke agbajiri agbaji agbaji agbajiri agbaji, igwe na-agbaji nwere Cr, Mo obere ọcha, ọ nwere nkwụsi ike dị mma n'ime nhazi. nnukwu carbon ígwè grit na obere carbin

-

FerroSilicon

Ferrosilicon bụ ụdị ferroalloy nke a na-emepụta site na mbelata silica ma ọ bụ ájá nwere coke n'ihu ígwè.Ebe a na-enwetakarị ígwè bụ ígwè a kpụrụ akpụ ma ọ bụ ihe igwe ihe.A na-eme Ferrosilicons nwere ọdịnaya silicon ruo ihe dị ka 15% n'ọkụ mgbawa ejiri brik ọkụ acid kpuchie.

-

Nkedo igwe anaghị agba nchara

Igwe anaghị agba nchara bụ ụdị mgbasa ozi na-ewu ewu karị.Ngwaahịa a na-eme otu ihe ahụ na ogbugba ígwè, Otú ọ dị, bụ nke igwe anaghị agba nchara.O nwere njupụta dị elu nke nickel na chromium.Ọ dịkwa mma mgbasa ozi ị ga-atụle mgbe mmerụ ahụ nke akụkụ ọrụ enweghị ike ịdị

-

Ndị na-ebu carbon

Carburizer, nke a makwaara dị ka onye na-emepụta ihe ma ọ bụ carburant, bụ ihe mgbakwunye na nchara ma ọ bụ nkedo iji mee ka ọdịnaya carbon dịkwuo elu.A na-eji ihe ndị na-emepụta ihe na-eme ka ígwè na-emezi ihe Carburizers na ígwè nkedo Carburizers, yana mgbakwunye ndị ọzọ na Carburizers, dị ka ihe mgbakwunye breeki, dị ka esemokwu esemokwu.

-

Silicon manganese Alloy

Silicon manganese alloy (SiMn) bụ silicon, manganese, ígwè, obere carbon na ụfọdụ ihe ndị ọzọ. Ọ bụ lumpy ihe na a silvery dara elu.Mmetụta nke mgbakwunye silicomanganese na nchara: Ma silicon na manganese nwere mmetụta dị mkpa na njirimara nke ígwè.

-

Barium-Silicon (BaSi)

Ferro silicon barium inoculant bụ ụdị alloy dabeere na FeSi nwere ụfọdụ barium na calcium, ọ nwere ike ibelata ihe oyi oyi n'ụzọ dị ịrịba ama, na-emepụta ntakịrị ihe fọdụrụnụ.Ya mere, Ferro silicon barium inoculant dị irè karịa inoculant nke nwere naanị calcium, na mgbasa ozi

-

Nodulizer (ReMgSiFe)

Nodulizer bụ ihe na-eri ahụ nke nwere ike ịkwalite ịmepụta graphite spheroidal site na mpempe graphite na usoro mmepụta.Ọ nwere ike ịkwalite graphites spheroidal ma mee ka ọnụ ọgụgụ nke graphites spheroidal dị elu ka emeziwanye ihe eji arụ ọrụ ha.N'ihi ya, ductility na toughnes

-

Strontium-Silicon (SrSi)

Ferro silicon strontium nucleating agent bụ ụdị alloy dabeere na FeSi nwere ụfọdụ barium na calcium, ọ nwere ike ibelata ihe oyi oyi n'ụzọ dị ịrịba ama, na-emepụta ntakịrị ihe fọdụrụnụ.Ya mere, Ferro silicon barium inoculant dị irè karịa inoculant nke nwere naanị calc

-

Calcium-Silicon (CaSi)

Silicon Calcium Deoxidizer bụ ihe mejupụtara silicon, calcium na ígwè, bụ ezigbo ogige deoxidizer, desulfurization agents.A na-eji ya eme ihe na nchara dị elu, obere carbon ígwè, mmepụta igwe anaghị agba nchara na nickel base alloy, titanium alloy na mmepụta alloy ndị ọzọ pụrụ iche.

-

Magnesium-Silicon (MgSi)

Ferro silicon magnesium Nodulizer na-agbaze alloy mejupụtara ụwa na-adịghị ahụkebe, magnesium, silicon na calcium.Ferro silicon magnesium nodulizer bụ ezigbo nodulizer nwere mmetụta siri ike nke deoxidation na desulfurization.Ferrosilicon, Ce + La mish metal ma ọ bụ obere ụwa ferrosilicon na magnesium bụ

-

FerroManganese

Ferromanganese bụ ụdị ferroalloy nke nwere ígwè na manganese. bụ nke a na-eme site na ikpokọta ngwakọta nke oxides MnO2 na Fe2O3, na carbon, na-emekarị dị ka coal na coke, na ma ọ bụ ọkụ ọkụ ma ọ bụ ọkụ ọkụ ọkụ eletrik ụdị usoro. nke a na-akpọ ọkụ arc miri emi.

-

FerroChrome

Ferrochrome (FeCr) bụ alloy nke chromium na ígwè nwere n'etiti 50% na 70% chromium. N'ime 80% nke ụwa ferrochrome ka etinyere n'ọrụ na mmepụta nke igwe anaghị agba nchara.Dabere na ọdịnaya carbon, enwere ike kewaa ya n'ime: High carbon ferrochrome/HCFeCr (C: 4% -8%), Ọkara carbon ferrochrome/MCFeCr (C: 1% -4%), obere carbon ferrochrome/LCFeCr (C: 0.25) % -0.5%), Micro carbon ferrochrome/MCFeCr: (C: 0.03-0.15%) .China maka ịbawanye oke nke mmepụta ferrochrome ụwa.

-

Ferro Molybdenum

Ferromolybdenum bụ ferroalloy nke mejupụtara molybdenum na ígwè, na-enwekarị molybdenum 50 ~ 60%, nke a na-eji dị ka ihe mgbakwunye alloy na nchara. ezigbo kristal

-

Igwe anaghị agba nchara Cut Waya Shot

Igwe anaghị agba nchara ịkpụ waya ogbugba bụ anyị akpan akpan specialty.It mere nke SUS200, 300, 400 usoro igwe anaghị agba nchara waya bee n'ime agba.A na-eji ogbunigwe gbutu igwe anaghị agba nchara na ọnụ ọgụgụ na-arịwanye elu nke ngwa dị mkpa ebe mmetọ ferrous na-agbawa igwe anaghị agba nchara, titanium.

-

Igwe igwe anaghị agba nchara akpara akpa

The esoroworị igwe anaghị agba nchara ogbugba mere nke SUS200, 300, 400 usoro igwe anaghị agba nchara waya na ala n'ime bọọlụ nke dị iche iche roundness.Stainless ígwè ogbugba nwere ezigbo okpomọkụ na-eguzogide, corrosion eguzogide, kenkowaputa surface.It nwere ike zuru okè mmetụta na igwe anaghị agba nchara workpieces.

-

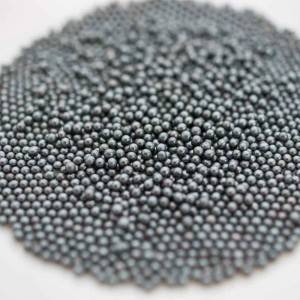

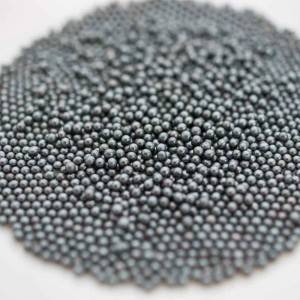

Igwe igwe gbara okirikiri Carbon dị elu

High carbon ígwè ogbugba, mere nke pụrụ iche ígwè, obi tara mmiri na iwe, nwere ọdịnaya na carbon karịrị 0.85% site atomization usoro, sppherical ahụ mere nke wụrụ awụ steel.Fengerda nditịm achịkwa ọ bụla njikọ nke mmepụta, karịsịa akara nke deoxidation na decarboniza

-

Igwe igwe gbara okirikiri Carbon dị ala

Igwe nchara carbon dị ala nwere obere carbon, phosphorus na sọlfọ karịa agba agba carbon ígwè dị elu.Ya mere, n'ime micro Ọdịdị nke obere carbon shot bụ nnọọ smoother.Obere carbon ígwè gbaa bụ softer tụnyere elu carbon ígwè gbaa kwa.

-

Aluminom gbara / ịkpụ waya gbara

Aluminom ịkpụ-waya ogbugba (Aluminom Shot) dị na ngwakọta aluminum akara ule (4043, 5053) yana alloy akara ule dị ka ụdị 5356. Anyị agwakọta akara ule na-enye n'etiti B nso (Odika 40) Rockwell hardness mgbe ụdị 5356 ga-emepụta Rockwell dị elu. B siri ike n'ogo 50 ruo 70.

-

Uhie ọla kọpa ogbugba/ọla kọpa ịkpụ waya gbara

1. Na-ewepu flash ruo 0.20" na nkedo anwụ na-emebighị elu

Na-ebelata ike ọgwụgwụ na mgbawa ngwa ngwa

Na-ewepụ agba na mkpuchi ndị ọzọ na-emebighị elu nke akụkụ ahụ

A na-etinye ihe nkiri dị nro nke zinc na akụkụ ígwè n'oge okirikiri na-enye nchebe nchara dị mkpirikpi -

Zinc shot/Zinc ịkpụ waya gbara

Anyị na-enye qualitative nso nke Zinc Cut Waya Shots.Dị n'ọnụọgụ ndị tozuru oke, ngwaahịa anyị na-ebelata ịka nká na ngwa mgbawa.Mpịakọta waya ndị a na-egbutu Zinc dị nro karịa igwe anaghị agba nchara ma ọ bụ ngwaahịa nkedo.Zinc cut wire shot dị na nha dị iche iche.

-

Egweri Steel Shot

Alloy egweri ígwè ogbugba dabeere na elu-carbon ígwè ogbugba, obere-carbon ígwè ogbugba, na obere vanadium ígwè ogbugba, na-atụle adịghị ike na-egbu egbu nke n'elu ngwaahịa: ikuku oghere, mgbawa, isiike iche, ịzụlite ọhụrụ ngwaahịa site reasrch na. teknụzụ na-arụ ọrụ, ọ nwere ike ịhọrọ ihe dị iche iche

-

Ịme bọọlụ nchara

A na-eji ígwè okirikiri eme bọọlụ a na-agbagharị agbagharị dị ka akụrụngwa, nke a na-ahazi n'anụ ahụ site na teknụzụ ịgbagharị ọhụrụ na nke a na-akpụ akpụ wee mepụta ya site na teknụzụ ọgwụgwọ okpomọkụ pụrụ iche.

Mgbe ọtụtụ afọ nke ahụmahụ mkpokọta na ule ugboro ugboro, -

Bee Waya Shot/Ọhụrụ Waya

A na-arụpụta Cut Waya Shot site na waya dị elu nke a na-egbutu n'ogologo ihe dịka dayameta ya.Enwere ike iji eriri Carbon Steel, igwe anaghị agba nchara, Aluminom, Zinc, Nickel Alloy, Copper ma ọ bụ ọla kọpa ndị ọzọ.Ọ ka nwere akụkụ dị nkọ site na ịkpụ

-

Bee Waya Shot/ejiri waya

The recycled steel cut wire shot bụ ụdị ngwaahịa nke na-eji ihe eji emegharịgharị ihe, ọnụ ahịa ihe ya dị ala, na-esikwa ike imepụta ngwaahịa dị elu, ụdị ngwaahịa a nwere ike iji mee ka ọ dị ọcha nkedo elu. Ọ na-abụkarị uesd na ọha. ebe.N'ihi na ndị ahịa na-enweghị pụrụ iche

-

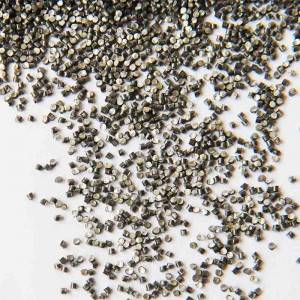

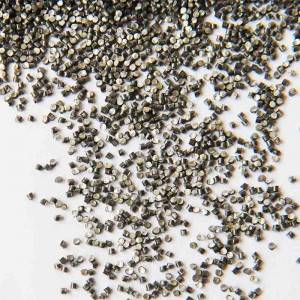

Carbon Angular Steel Grit dị elu

Akwa carbon angular ígwè grit na-arụpụtara site na nnukwu carbon ígwè ogbugba.Igwe igwe agbajiri agbaji ruo n'ụdị grit granular wee mee ka ọ dị ọkụ atọ dị iche iche (GH, GL na GP) iji kwado ngwa dị iche iche.A na-eji nnukwu carbon ígwè grit mee ihe dị ka mgbasa ozi maka descali

-

Carbon Angular Steel Grit dị ala

A na-arụpụta grit dị ala carbon angular site na obere carbon ígwè

ogbunigwe.Steel shots na-egweri na granular grit.Free nke ntụpọ n'ihi okpomọkụ ọgwụgwọ ebe ọ bụ na ọzọ ọgwụgwọ adịghị mkpa.

- Ekwentị

- 0086-632-5985228

- info@fengerda.com